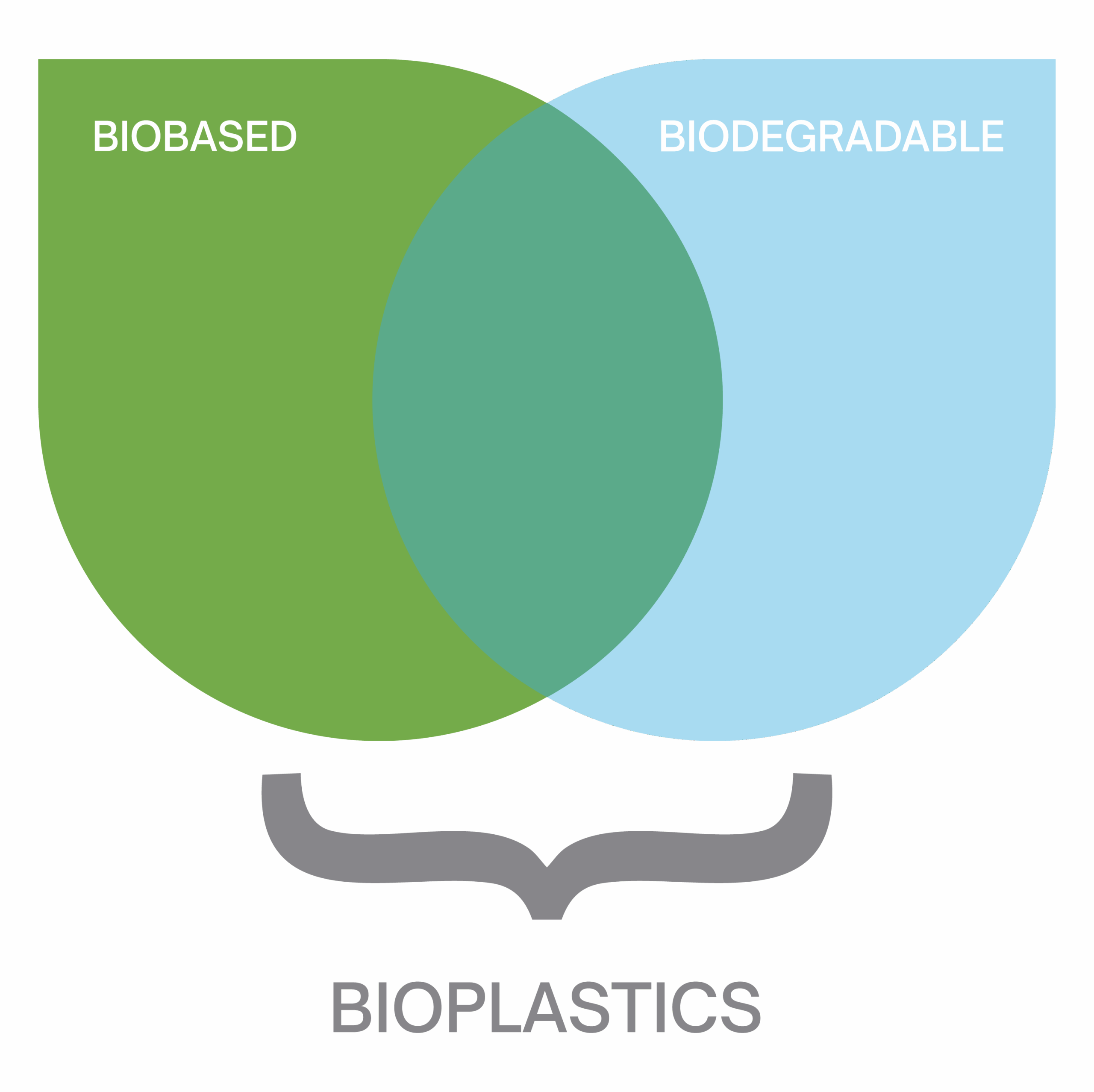

Bioplastics are a plastic that is either biobased and/or biodegradable. These materials are another sustainable material of choice due to the benefits they bring at both the beginning and end-of-life processes.

PLASTICS believes that bioplastics are an integral part of the plastic supply chain. Bioplastic products play a vital role in our daily lives and in plastic sustainability.

This webpage is meant to provide educational information about a bioplastics’ life cycle and the value that these materials bring both in function and in environmental impact. PLASTICS provides this information in good faith and is believed to be reliable when written.

In addition to general information about this material, you’ll also find a full content library, information about PLASTICS Bioplastics Division and two programs you can get involved with.

Biobased bioplastics typically lead to a reduction in a product’s carbon footprint and global warming potential (GWP) because the biobased carbon content is typically CO2 captured from the atmosphere through plant growth.

Compostable bioplastics, when disposed of properly, reduce the amount of waste sent to landfill and can help to bring more organic scraps (food and yard waste, for example) to commercial composting facilities while completely degrading back into useful compost themselves.

Bioplastics are used in the same ways as other plastics in packaging, agriculture, medical, automotive parts, 3D printing and more.

To be a bioplastic, the material must either:

Bioplastics can also be both biobased and biodegradable.

Bioplastics make up 1.5% of the over 489 million tons of plastic globally produced.1

1 2022 European Bioplastics data

2 PLASTICS Response & Recommendation to the Bold Goals

US bioplastic resin production is estimated to be 0.71% of total plastic production in 2023, or 0.89 billion pounds of 125.5 billion pounds, making the U.S. the second largest global producer of bioplastic resin.2

Global production of bioplastics is projected to increase by 48% annually. Reaching 7.43 million tons by 2028. US growth projections hover around 14% annually.

Nevertheless, this environmental attribute of these products should NOT be considered license to litter. Bioplastics, like all products, should be disposed of via the proper channels.

Bioplastics can be either partially or fully made from biobased content. Some biodegradable plastics are even made from fossil sources. For those that are biobased, the type of feedstock used is categorized into three generations.

| Generation 1 | Generation 2 | Generation 3 |

|---|---|---|

| Feedstocks from food-based crops | Feedstocks from non-food biomass | Feedstocks from non-land crops |

| Examples: Corn, sugar beets, rapeseed (used to make canola oil), soybeans, wheat, sunflower oil, and potatoes. | Examples: husks, stalks, peels, grasses, straw, and wood. | Examples: seaweed or algae |

*Examples listed in each category are not exhaustive lists.

While some bioplastics are fossil-based, many bioplastics are derived from biobased sources, meaning their carbon originates from renewable plant materials rather than fossil fuels. The core principle is simple: follow the carbon as it moves from the atmosphere into plants and eventually into plastic products. The production process involves converting plant-derived sugars or starches into the desired polymer through a series of chemical transformations. These steps are outlined below:

Here is a list of the most common bioplastic polymers that are commercially available. This includes information about each polymer’s characteristics. Some biobased polymers are chemically identical to their fossil-based counter parts (i.e., biobased PP = fossil-based PP).

When processing bioplastics, it is important to consider their material characteristics and manufacturability. Many bioplastics have a higher moisture content, higher viscosity, and higher sensitivity to heat than traditional (non-biobased and non-biodegradable) plastics.

These material characteristics can require adjustments to your manufacturing process. For instance, resins with a higher moisture content will require drying before and sometimes during processing, a higher viscosity in resin can require higher pressure to be used, and a higher sensitivity of heat can require close monitoring of temperature in both the pre-treatment drying and processing phases. When not properly managed, bioplastics can cause corrosion and leakage in equipment which would require more frequent repairs. Inspecting and maintaining your equipment frequently is recommended.

If you are manufacturing with a new polymer or additive, test, don’t guess!

Many companies are innovating plastic manufacturing equipment so that bioplastics can be more efficiently and effectively processed. Innovations include:

Many companies use bioplastics in their products for the material characteristics and environmental attributes they offer. For instance, compostable bioplastics can break down fully in a compost environment, just like, say, an apple core would. Therefore, compostability is an attractive material characteristic for products like food contact packaging. Biobased bioplastics tend to lead to a reduction in a product’s carbon footprint. Therefore, companies looking to reduce their scope 3 carbon emissions may find biobased bioplastics an attractive option.

Depending on the polymer formulation, bioplastics can be used in disposable or durable applications. Due to their variety, a wide range of industries utilize bioplastic materials, including building and construction, restaurants/grocery, agriculture, packaging, automotive, healthcare, textiles, electronics, consumer goods, and more. Below are a few examples of where you can find bioplastics in your day-to-day life.

Click here to see some examples of where you can find bioplastics in your day-to-day life.

Biodegrading >

It’s important to acknowledge that while all compostable products are biodegradable, not all biodegradable products are compostable. It is best practice to avoid using biodegradability claims in consumer-facing marketing in order to reduce risk of littering. There are, however, some business-to-business (B2B) applications in which using a “biodegradability” claim may be prudent.

Soil biodegradability is useful for agricultural and landscaping applications including mulch films, which can be tilled into the field after use instead of being removed and landfilled. Marine biodegradability can be useful in products that are designed for use in salt or freshwater environments.

*No form of biodegradation should be considered as a solution to littering.

Composting >

Recycling >

2016 Bioplastics Market Watch Report

Bioplastics are plastics that either: originate from a renewable resource, are biodegradable, or are both. As new applications and technologies are developed, bioplastics represent an evolution within the plastics marketplace. Bioplastics are part of the plastics’ growth story that is inspiring brand owners and manufacturers to find new applications and solutions for products.

2018 Bioplastics Market Watch Report

Phase two of the Bioplastics Market Watch Report, Watching: Bioplastics provides valuable updates on the status of bioplastics in the marketplace as well as at research labs around the country. Uncover information on innovation and advancement, market intelligence, consumer perceptions, emerging markets and public policy. Bioplastics are increasingly being used in industry sectors beyond bottling and packaging with many brands discovering their diversity and flexibility. The entire plastics supply chain can benefit from these insights.

2024 Bioplastics Market Watch Report

Phase 3 of the Bioplastics Market Watch Report offers valuable updates on the status of bioplastics in the marketplace, including research labs across the country. The report covers areas such as innovation, market intelligence, consumer perceptions, emerging markets, and public policy. It highlights the expanding use of bioplastics beyond bottling and packaging and explores the diversity and flexibility they offer. The insights provided in this report can benefit the entire plastics supply chain, offering valuable information for industry stakeholders.

This position paper outlines issues and questions of concern in order to support consumers, retailers and the plastics industry in identifying unsubstantiated and misleading product claims around degradability and biodegradability of plastics.

Commercially Compostable Bioplastics

This position statement identifies the credentials needed for a bioplastic to be considered certified commercially compostable and supports composting of this material to help meet sustainability goals.

Mass Balance (coming soon)

Required Use of Recycled Content (coming soon)

Bioplastics Simplified: Attributes of Biobased and Biodegradable Plastics

The term “bioplastics” describes a wide range of materials. This paper discusses the growing field of bioplastics and how material innovations can offer environmental advantages.

Industrial Compostability Claims Checklist

The Federal Trade Commission’s Green Guide provides direction to companies making claims about industrial compostability. This guidance document provides a handy checklist and examples about things to consider when putting claims on product packaging.

Life Cycle Analysis (LCA) Primer: What, Why, and How

This guide will describe what constitutes an LCA, what the benefits and limitations of different types of LCAs and related tools are, and how to interpret and communicate LCA results.

Voluntary Guidelines for Bioplastic Marketing Claims

All companies have the responsibility to ensure that environmental claims used in marketing and promotion are truthful and evidence-based, not deceptive or unfair. These recommendations are voluntary guidelines and general principles for those marketing bioplastics, informed by the Federal Trade Commission (FTC) “Guides for the Use of Environmental Marketing Claims” (Green Guides) and relevant state laws or regulations.

The Bioplastics Division of PLASTICS works to promote the development of bioplastics as an integral part of the plastics industry through:

Interested in joining the Bioplastics Division? You must be a PLASTICS member and work within the bioplastics industry in some capacity.

To learn more about the Bioplastics Division or inquire about joining, email [email protected].

These two programs are open to anyone to participate in, regardless of PLASTICS membership. Click either tile to learn more about our award program and educational campaign.