July 15, 2024

For years, injection molding has been used to manufacture most plastic products. This technique may be efficient for mass production but has high tooling expenses, long lead times, and limited design flexibility.

These are barriers for many businesses, hence the need for alternative production methods. One emerging technology has shown great potential — a new process that allows the molds to be 3D printed instead of machined.

Let’s take a look at one example of this innovative technology and how it reduces plastic design costs.

Consumer goods company Unilever and plastic packaging manufacturer Serioplast Global Services have adopted a new technology from Formlabs, a 3D printing technology developer and manufacturer.

The new 3D printing technology enables faster and lower-cost prototyping of plastic packaging compared to traditional molding and maintains high-quality standards.

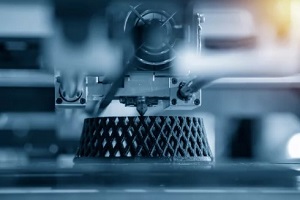

The 3D-printed molds used in the new technology are made from Rigid 10K Resin and produced layer-by-layer using a large-format stereolithography (SLA) 3D Printer.

Rigid 10K Resin is one of the stiffest resins available for SLA 3D printing, with a tensile modulus of 11 GPa. It is ideal for printing molds that require high rigidity and structural integrity, making them durable and having minimal flex.

The resin is suitable for applications where precise geometries are vital, such as mold printing, as it has high dimensional stability. Its formulation ensures minimal shrinkage upon curing.

3L is an industrial-grade, large-format SLA 3D printer designed for batch production of parts. Its large build volume of 33.5 x 20 x 30 cm can print larger and multiple molds in one go. The size capability reduces production time and costs.

The stereolithography (SLA) 3D printing technology uses light irradiation to cure liquid resins into solid parts, resulting in high-resolution and detailed prints. The technology also uses an advanced optical system that ensures precise laser control to create uniform prints.

Additionally, the technology allows for quick iteration and modifications of molds without expensive tooling changes, reducing valuable lead times and costs.

Join our PLASTICS Pulse newsletter today to receive updates on within the plastic industry while staying informed & connected.

Plastic packaging manufacturers have started using the new technology to print molds and create prototypes. The results have been remarkable, with the following benefits being noted during testing:

With the SLA 3D printing process, plastic packaging manufacturers can reduce their mold production time from a few weeks to a few days. For example, Serioplast can produce resin molds in just two days.

Previously, the company outsourced mold production using traditional machining processes that would take four to eight weeks. SLA cuts down the time by up to 2,000% and increases throughput.

3D-printed molds reduce the lead time for pilot testing of blow-molded plastic bottles. It would take six to eight weeks to produce 200 bottles with conventional molds. This process takes only two weeks with the printed molds.

Machining a metal mold using traditional methods costs $2,500 to $10,000, including tooling and raw materials. The SLA 3D printing process requires only $500 to $1,000 which translates to up to 90% cost savings.

As an industrial-grade resin, Rigid 10K can withstand the high pressures involved in blow molding processes. It also exhibits high thermal resistance. The printed molds have already been tested using 30 bar pressure and 100°C temperature to produce the bottles.

The mold proved up to standard, as there was no wear on the cavity of the 3D printer mold. Also, the sample bottles met the standard required for mass production and commercial distribution. The SLA 3D printer and 10K Resin allow for the inclusion of vivid and precise details on the bottles, which allows embossing of intricate logos.

To date, this innovative method has proven reliable for producing prototype bottles. The 15 bottle designs produced so far have passed the line and consumer testing.

The production started with the creation of a standard mold design and print preparation, and the mold cavity was later modified for each design. This ensured rapid iteration, subsequently speeding up the pilot evaluations by allowing for the simultaneous testing of multiple designs, thereby accelerating the design-to-market process.

The stretch blow-molding process for the 15-bottle designs was also tested and validated. This included an evaluation of dimensional accuracy and performance, covering cupping, bulge, and drop testing. All metrics met the required standards.

The Plastics Industry Association provides its members with up-to-date industry information, market intelligence, and insights to help them evaluate emerging technologies. We can help you stay on top of the latest trends and industry innovations. Contact the Plastics Industry Association today to become a member.

PLASTICS and the Future Leaders in Plastics (FLiP) Committee are devoted to supporting and encouraging the next generation of plastics leaders who will play a crucial role in the innovation, technology and future of the plastics industry. FLiP’s mission is to provide young professionals under the age of 40 the exposure, education and resources they need to build lifelong careers in plastics. Want to join? Want to get your employees involved? Email: [email protected]